Welding

- Steel – TIG, MIG, Spot

- Aluminum – TIG, MIG

- Stainless Steel – TIG, MIG

Shearing

Capable of shearing up to 12’ of:

- ¼” Mild Steel

- 3/16” Abrasion Resistant Steel (AR Plate)

- 3/16” Stainless Steel (most alloys)

- 3/8” Copper/Brass

- 3/8” 5052 Aluminum

- ¼” 6061 Aluminum

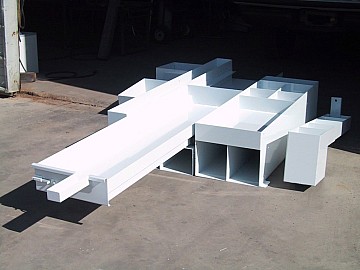

Bending (forming)

- Steel – 3/16” x 12’ long.

- Aluminum – ¼” x 12’ long.

- Stainless Steel – 3/16” x 12’ long.

Tapping

Most materials up to ½ threads with standard taps using our pneumatic tapping arm.

Hole Punching

We operate 2 hydraulic punches and can punch a variety of sizes and material thicknesses. Call us for more specifics.Materials too thick or holes too large can be waterjet cut. See our Waterjet page for more details.

Square & Round Tube Bending

Square and Round Tubing Bending:

- 2” Round tube – 6” radius

- 1 ½” Round tube – 6” radius

- 1 ¼” Round tube – 4” radius

- 1” Round tube – 2 ½” & 4” radius

- 1” Square tube – 4”, 5”, & 6” radius (can also roll larger radii with our tube roller)

Rolling

- 16ga x 36” x 6” diameter and larger

- Square tube

- Flatbar

- Angle iron

- Channel

Saw Cutting

- Up to 12” wide most materials.

- Up to 60°

Waterjet Cutting

- Max dimensions – 55” x 96” x 8” thick…ANY MATERIAL

- Tolerances - ± .005”

Plasma Cutting

- Steel – Up to 1 ½” thick

- Aluminum – Up to 1” thick

- Stainless Steel – Up to 1 ½” thick

Oxy/Acetylene Cutting

- Up to 2” thick